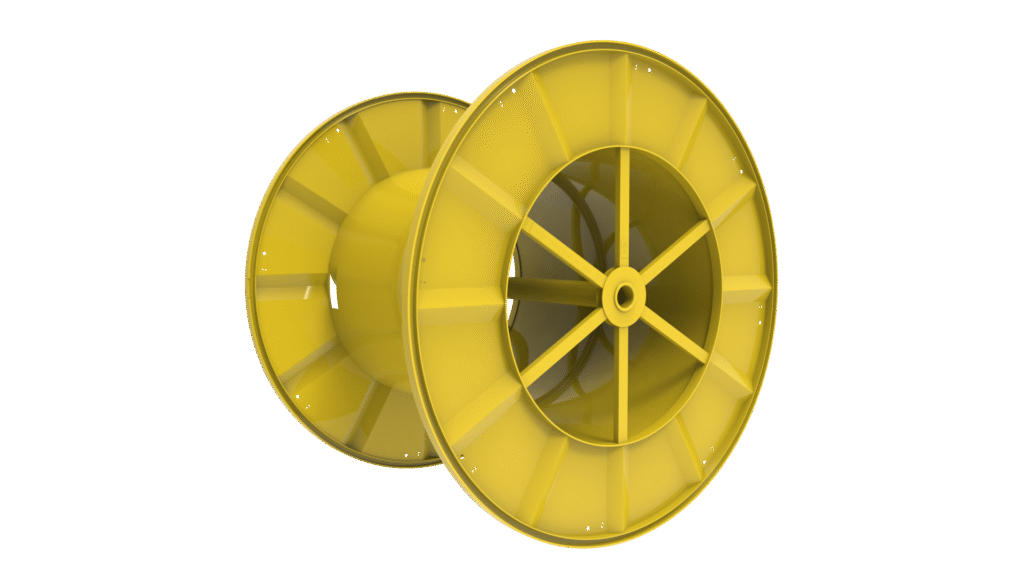

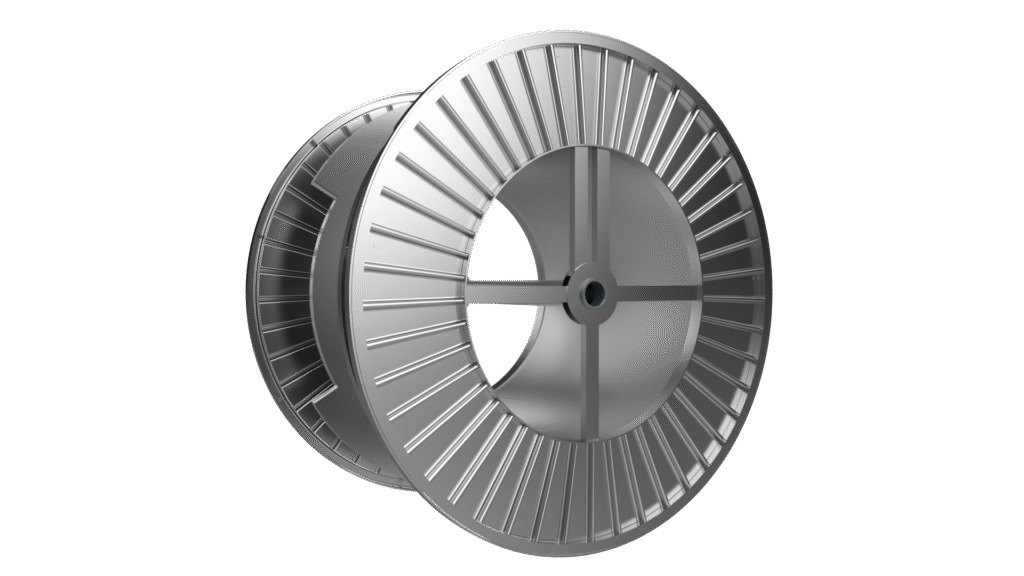

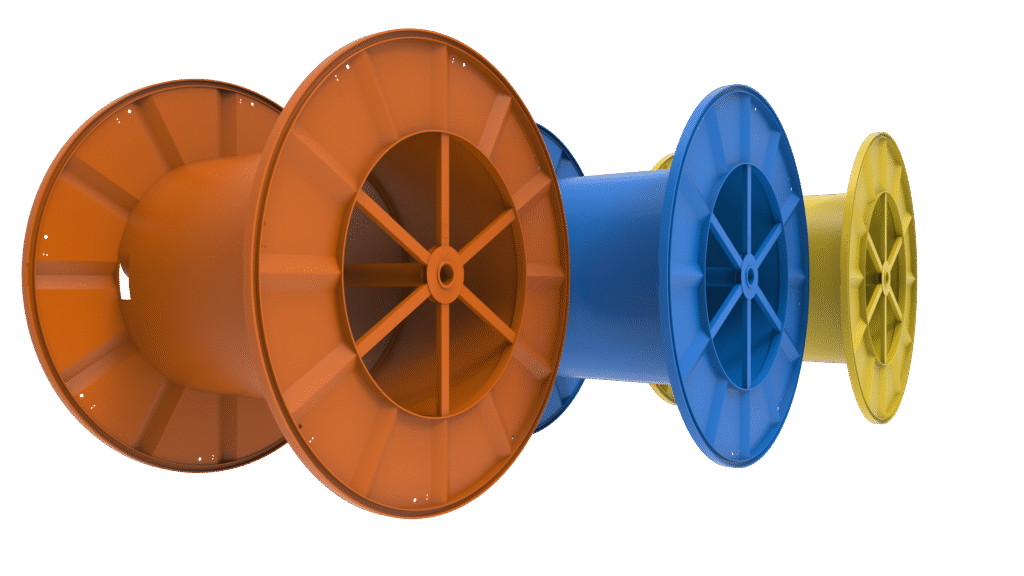

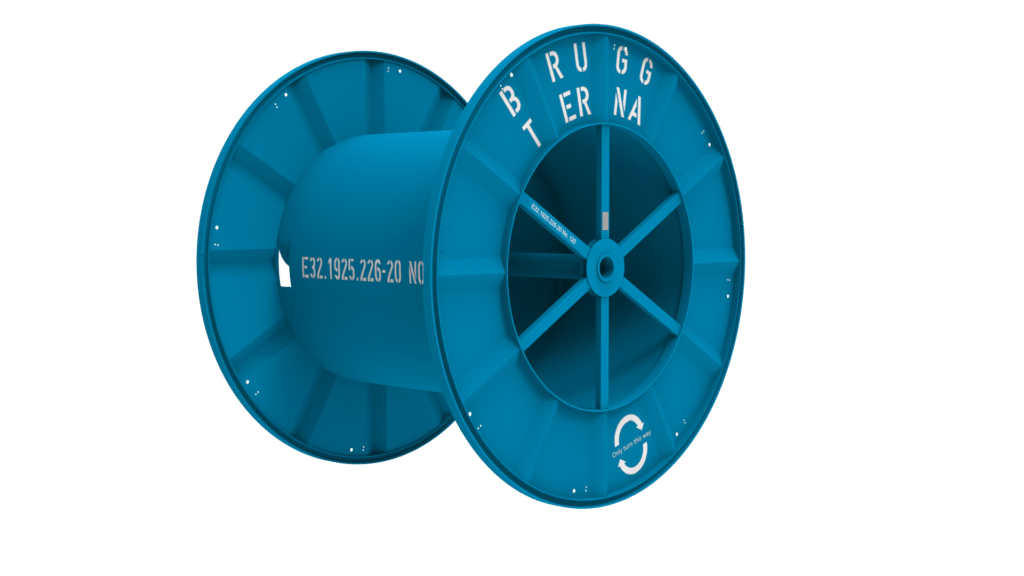

Steel reel cable drums are robust, reusable storage and transport units made from high-strength steel. They are designed to carry, wind, unwind, and protect cables or hoses during handling and transportation. These drums are ideal for heavy-duty applications, long cable lengths, and harsh environmental conditions (construction, offshore, mining, or industrial installations).

Construction & Design

| Component | Description |

|---|---|

| Flanges | Circular steel discs forming the two sides of the drum. Usually made from hot-rolled mild steel plates (e.g., S235JR or equivalent). Reinforced with stiffeners or ribs to prevent deformation. |

| Barrel/Core | Cylindrical section connecting the flanges, used to wind the cable. Typically made from welded steel sheet or tubular structure. Barrel diameter is sized according to cable bending radius. |

| Hub/Bearing Assembly | Central hub to allow rotation when mounted on a shaft. Can include bushings or bearings for smooth unwinding. |

| Welding | Fully welded or bolted structure ensuring rigidity and reusability. Welds comply with ISO 5817 (Quality Level C or better). |

| Surface Treatment | Usually shot-blasted and coated with primer and industrial enamel or hot-dip galvanized to ISO 1461 for corrosion resistance. |

Design Standards & Compliance

- DIN 46391 – Steel cable drums for heavy-duty use

- DIN 46395 – Reels for wire and cable transport

- ISO 7808 – Reels for electric cables — Basic dimensions

- EN ISO 1461 – Hot-dip galvanized coatings

- ISO 8501-1 – Surface preparation for painting