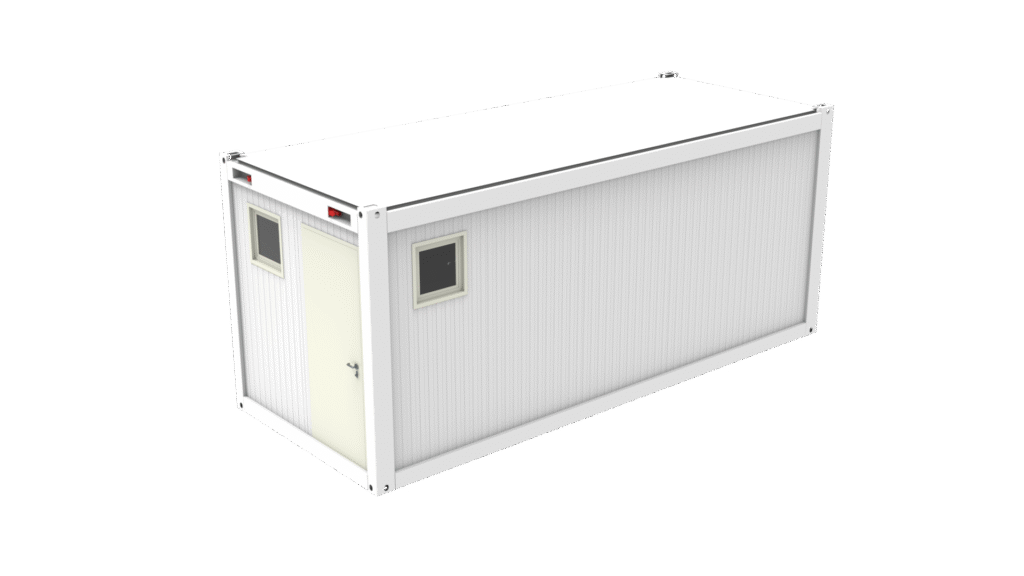

A prefabricated mobile container house is a modular, factory-built housing unit often made from a steel frame and sandwich-panel walls that is designed for transport and relatively rapid installation.

All major components are manufactured in a controlled environment:

Frame Construction

- Galvanized steel or cold-rolled steel columns and beams.

- Structural welding ensures rigidity.

- Corner castings for lifting and transport.

Walls, Roof & Floor Panels

- Sandwich panels: EPS, PU, or rock wool core with steel/aluminum sheets.

- Pre-cut doors, windows, and openings installed in panels.

- Panels are cut to size and ready for assembly.

Utilities Pre-Installation

- Electrical wiring: lights, sockets, switches pre-routed.

- Plumbing: pre-installed pipes, bathrooms, kitchen connections.

- Optional HVAC, solar wiring, or smart systems.

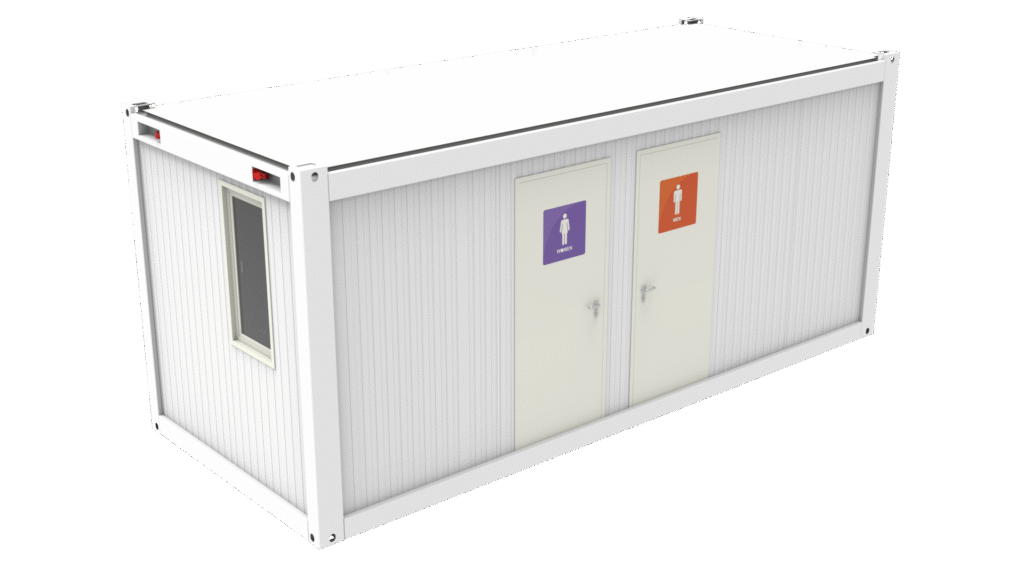

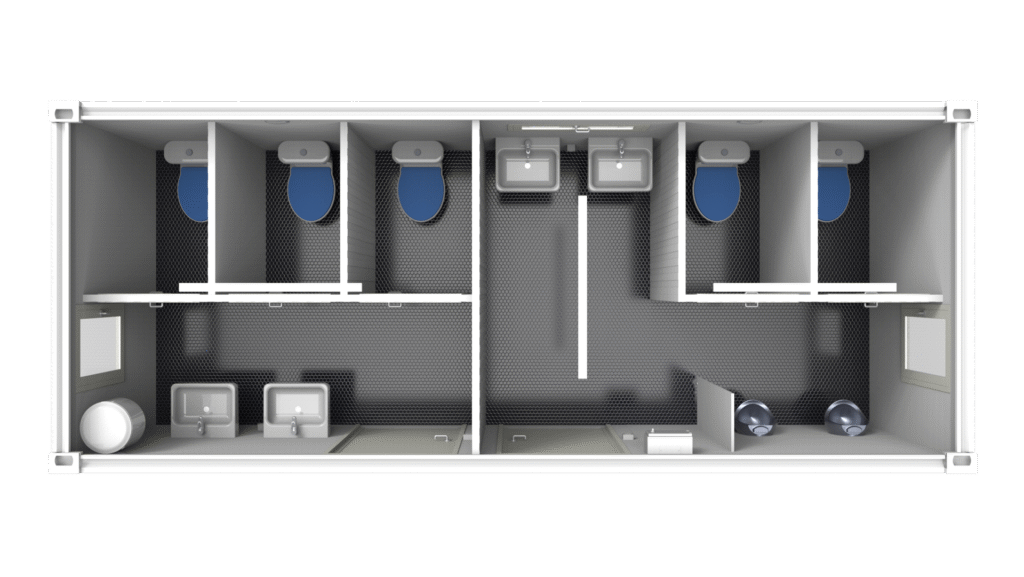

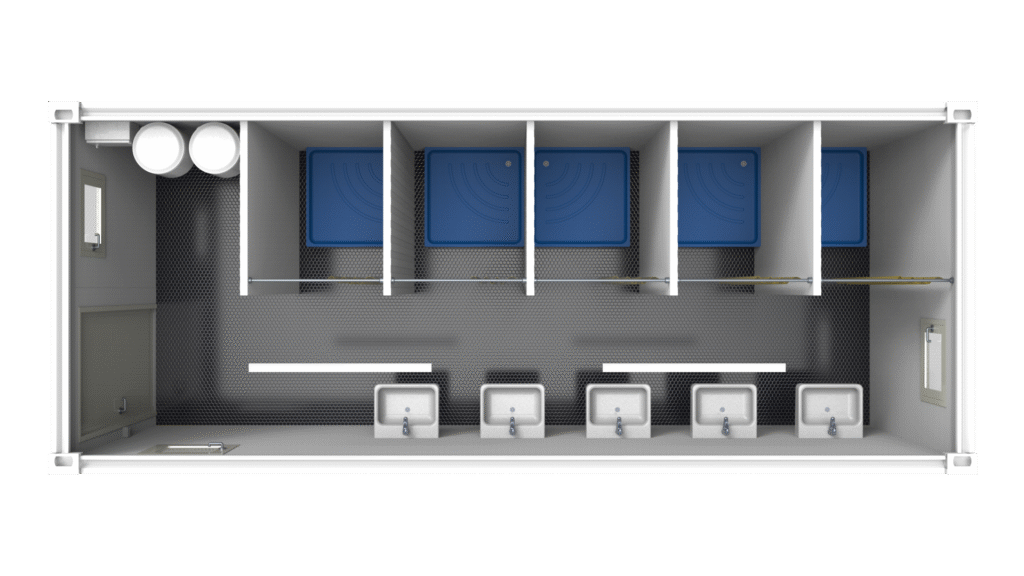

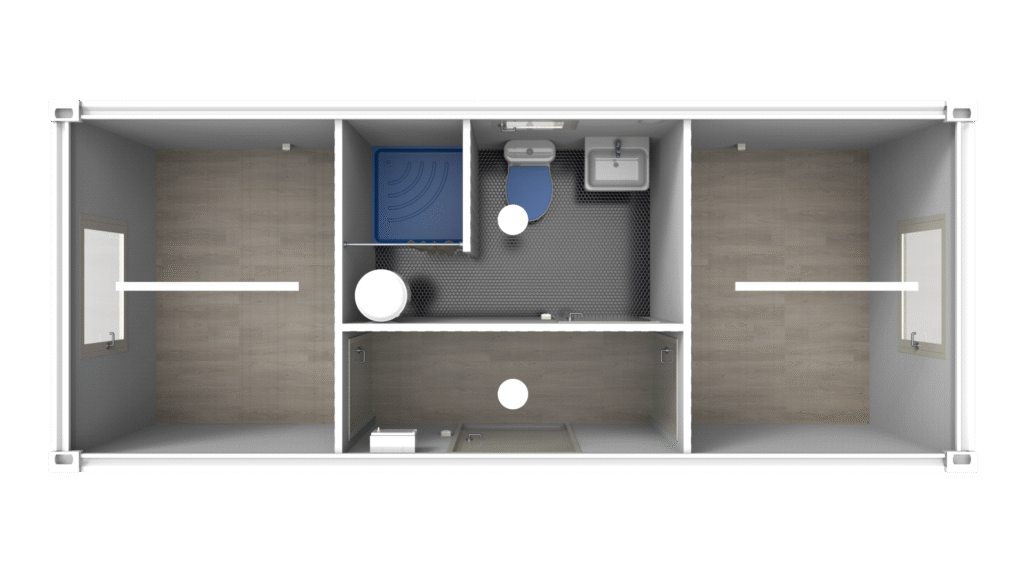

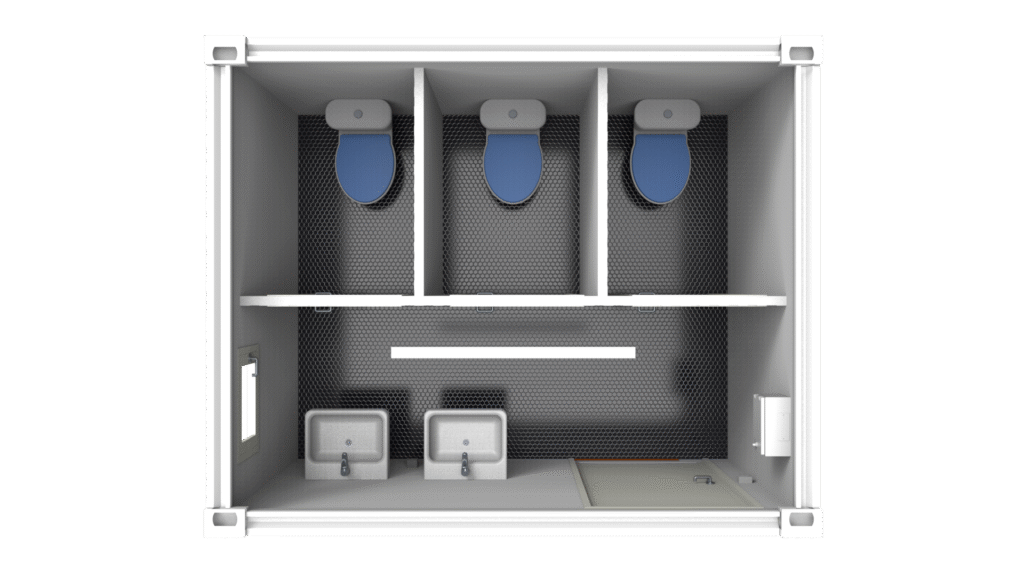

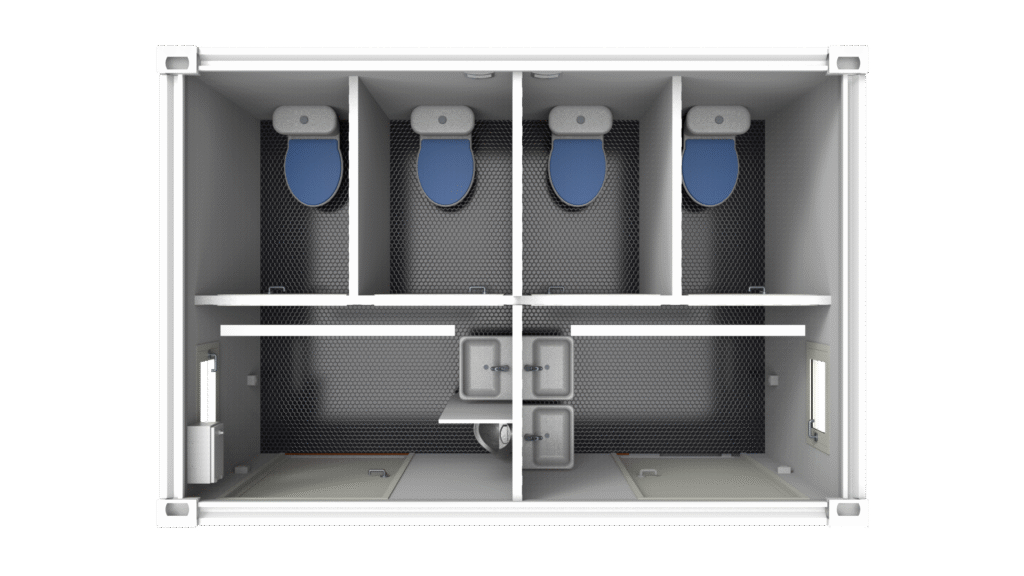

A prefabricated mobile container house with a bathroom is a modular, transportable steel or sandwich-panel structure that comes ready-made with integrated plumbing, bathroom, and sometimes a small kitchen.

Bathroom Included: Typically includes a shower, toilet, sink, and sometimes a vanity.

Self-contained Utilities: Pre-installed plumbing and electrical wiring; just connect to water and power.

Compact & Efficient Layout: Bathroom usually 2–4 m², designed to maximize living space.

Mobility: Can be relocated easily; ideal for temporary or semi-permanent setups.

Insulated Walls & Roof: EPS, PU, or rock wool sandwich panels for thermal and sound insulation.

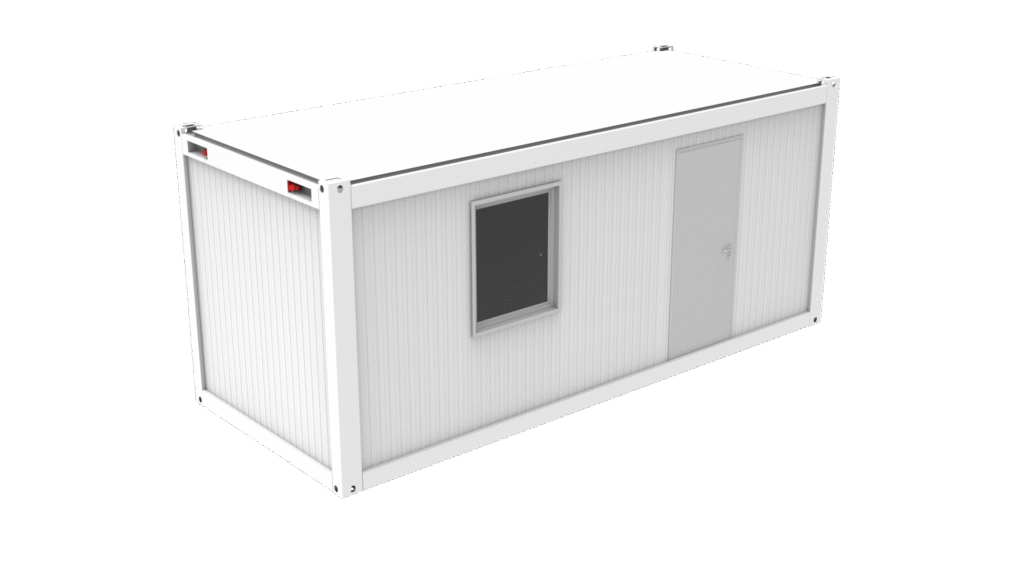

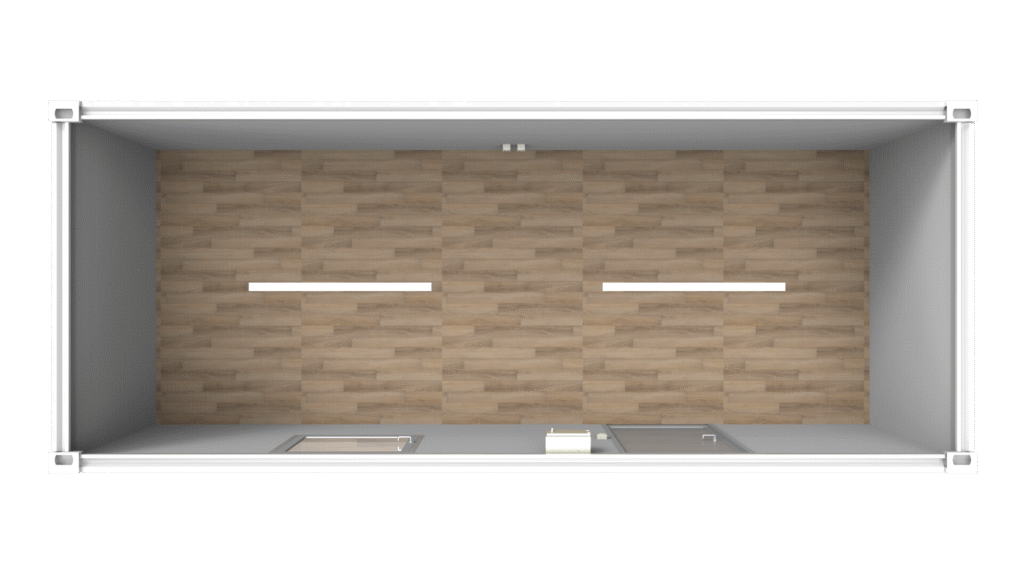

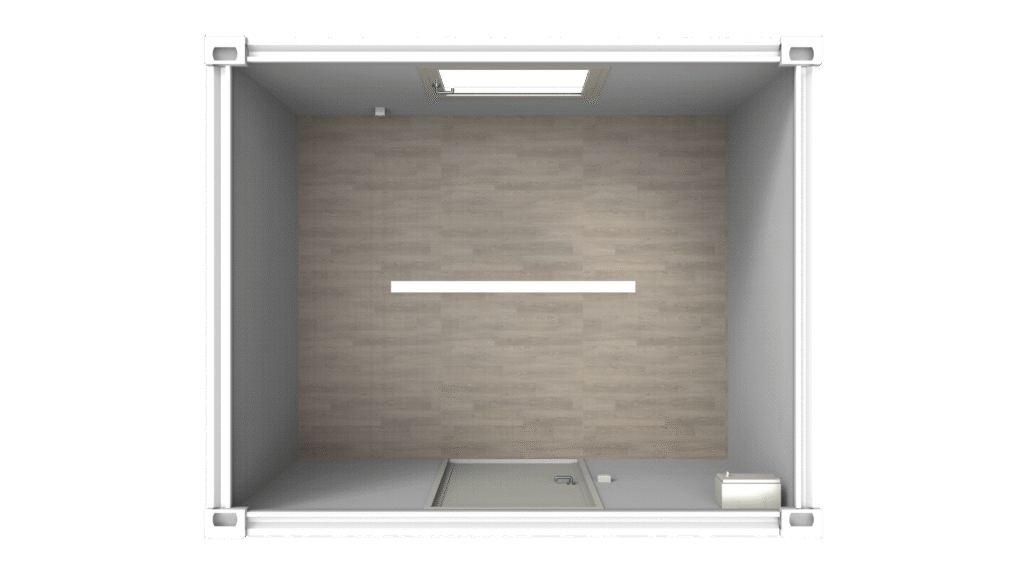

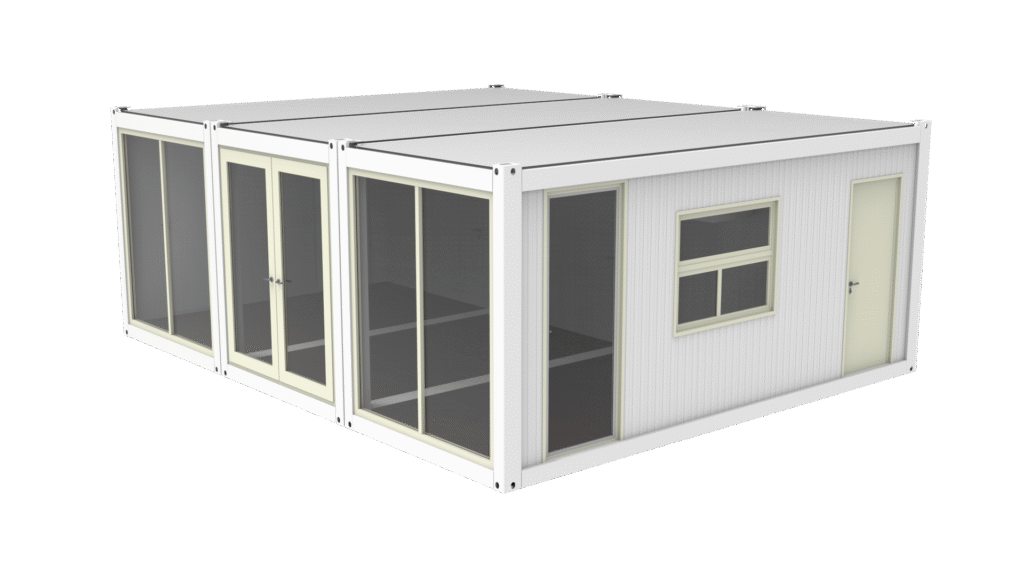

A prefabricated mobile container office is a modular, factory-built unit made from steel and insulated panels, designed to function as a fully equipped workspace.

Mobility: Can be transported and set up quickly at any site.

Prefab Design: Built in a factory for consistent quality and rapid deployment.

Durable Structure: Steel frame and sandwich panel walls ensure weather resistance and longevity.

Utilities Ready: Pre-installed electrical wiring, lighting, HVAC, and sometimes plumbing.

Expandable: Multiple units can be joined side-by-side or stacked for larger offices.

✅ Advantages of This Construction Method

- Speed: Factory-made panels reduce on-site construction time.

- Mobility: Can be relocated multiple times.

- Customization: Modular panels allow different layouts, fold-outs, or stackable units.

- Durability: Steel structure + insulated panels offer long lifespan (15–30 years typical).

- Eco-friendly: Less waste, less concrete, recyclable steel.