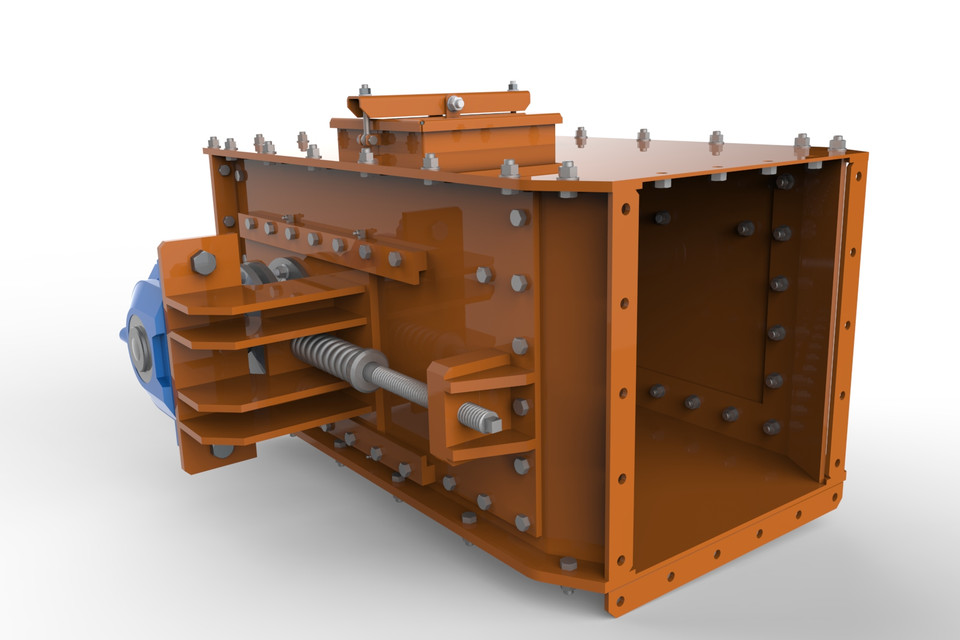

The take-up head is a critical component of a belt conveyor system, responsible for maintaining proper tension in the conveyor belt. The Belt conveyor take-up head ensures that the belt operates efficiently and reduces wear and tear on both the belt and the conveyor components.

Key Components

- Take-Up Frame

- Structure: Typically made of steel or other durable materials to withstand tension and environmental conditions.

- Mounting: Fixed to the conveyor structure, allowing for adjustment of the take-up mechanism.

- Tensioning Mechanism

- Types:

- Mechanical Take-Up: Utilizes a winch or screw mechanism to adjust tension manually.

- Hydraulic Take-Up: Uses hydraulic cylinders for automatic tension adjustment.

- Adjustment Range: Designed to accommodate belt elongation over time and environmental factors.

- Types:

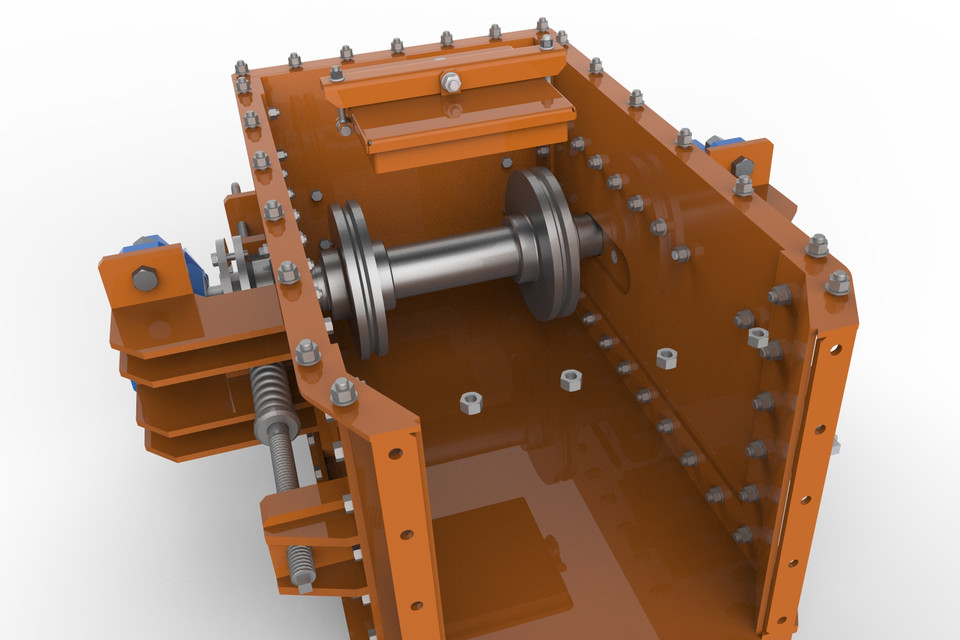

- Pulley

- Design: The take-up pulley is often larger than standard pulleys to provide better grip and support for the belt.

- Material: Generally made of steel or rubber-coated for enhanced friction and durability.

- Belt Alignment and Support

- Guides and Rollers: Ensure the belt remains aligned and supported as it passes through the take-up area.

- Impact Rollers: May be included to absorb shock and reduce wear.

Functions

- Tension Maintenance: Keeps the belt taut to prevent slippage and ensure efficient operation.

- Belt Tracking: Helps maintain proper alignment of the belt, reducing misalignment issues.

- Compensation for Wear: Allows for adjustments as the belt stretches or wears over time.